Knife gate valve

Key words:

Knife gate valve

Product Introduction

- Product Description

-

1. Product Overview

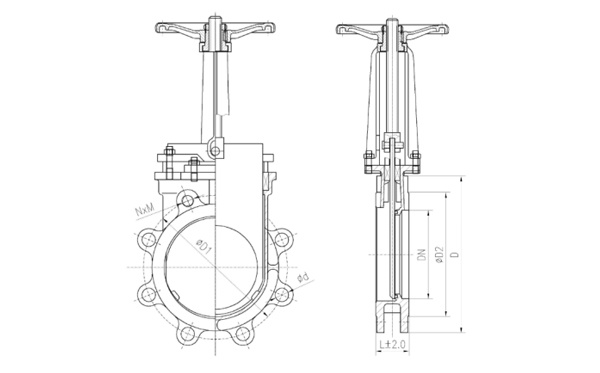

Knife gate valve is also called knife gate valve and knife type slurry valve. Its opening and closing part is a gate. The movement direction of the gate is perpendicular to the fluid direction. The medium is cut off by a blade-shaped gate that can cut fiber materials. The gate has two sealing surfaces. The two sealing surfaces of the most commonly used mode gate valve form a wedge shape. The wedge angle varies with valve parameters, usually 50. The gate of the wedge type knife gate valve can be made into a whole, called rigid gate; can also be made to produce micro deformation of the gate, in order to improve its process, make up for the sealing surface angle in the process of deviation, this kind of gate is called elastic gate. In fact, there is no chamber in the valve body. The gate is lifted in the side guide groove and pressed on the valve seat by the lug at the bottom. If a higher medium sealing performance is required, an O-shaped sealing valve seat can be used to realize two-way sealing. The knife gate valve has a small installation space, low working pressure, not easy to accumulate debris, and low price.

When the knife gate valve is closed, the sealing surface can only rely on the medium pressure to seal, that is, rely on the medium pressure to press the sealing surface of the gate to the other side of the valve seat to ensure that the sealing surface is sealed, which is self-sealing. Most knife gate valves are forced to seal, that is, when the valve is closed, it is necessary to rely on the external force to press the gate to the valve seat to ensure the sealing surface. This type of valve in the pipeline should generally be installed horizontally.

2. product performance characteristics

1. The lifting type gate sealing surface can scrape off the adhesion on the sealing surface and automatically clean up the debris.

2. Stainless steel gate can prevent seal leakage caused by corrosion.

3. The hard all-gold sealing surface can ensure the sealing wear resistance and requirements.

4. There is no groove on the sealing surface of the valve body, which does not produce accumulation and can ensure flexible opening.

The short structure length is short, which can save raw materials, install space and effectively support the pipeline strength.

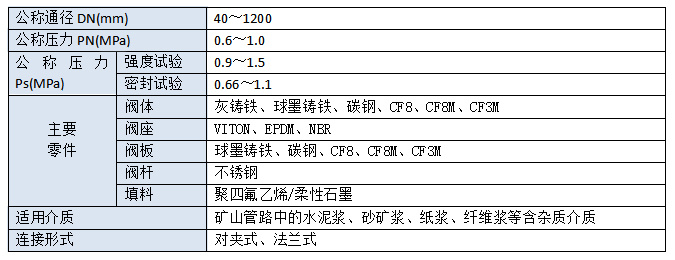

3. product specifications

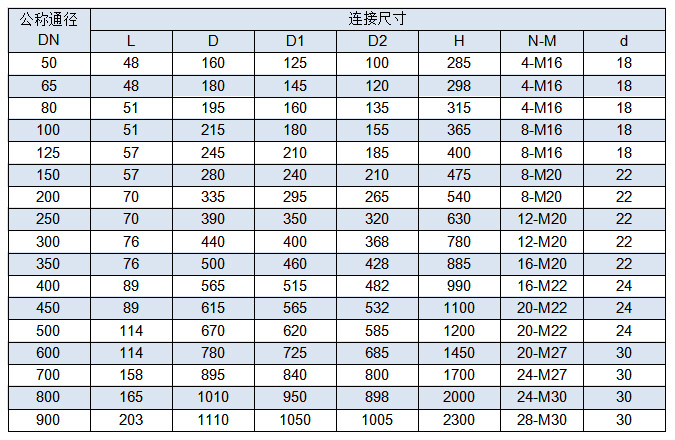

4. product connection size

Product inquiry

Leave your contact information to get a free product quote