Pneumatic wafer-lined fluorine butterfly valve

Key words:

Pneumatic wafer-lined fluorine butterfly valve

Product Introduction

- Product Description

-

1. Product Overview

Lined with PTFE butterfly valve is to adapt to some strong acid, strong alkali corrosive environment, petroleum, chemical, food and other special areas of the need, in the regular butterfly valve valve and valve plate lined with PTFE, so that the medium and the body isolation, to achieve the effect of anti-corrosion. Lined with PTFE butterfly valve, rubber-lined butterfly valve as a pipeline system used to achieve on-off and flow control components, has been in the petroleum, chemical industry, metallurgy, hydropower and many other fields have been extremely widely used. In the well-known butterfly valve technology, its sealing form is mostly sealed structure, and the sealing material is rubber, polytetrafluoroethylene, etc. Due to the limitation of structural characteristics, it is not suitable for industries such as high temperature resistance, high pressure, corrosion resistance and wear resistance.

2. product performance characteristics

1. Simple structure, small size and light weight.

2. Strong corrosion resistance, stable performance, not easy to age, low friction coefficient.

3. Seamless valve body design ensures the sealing type of valve body and valve seat and the uniform force of valve body and valve seat.

4. Adjustable gland design to extend the service life of the valve body.

5. Two-way sealing to ensure that the medium does not leak.

6. Integrated valve stem disc design, enhanced sealing type, ensure torque.

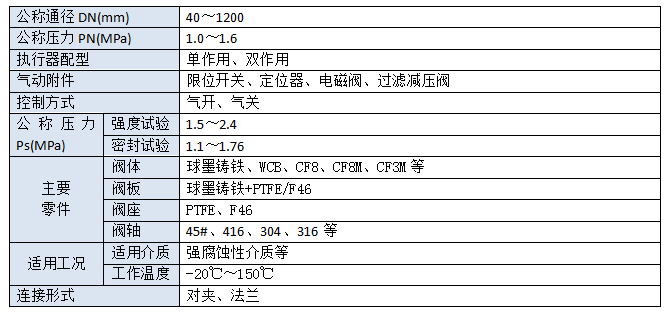

3. product specifications

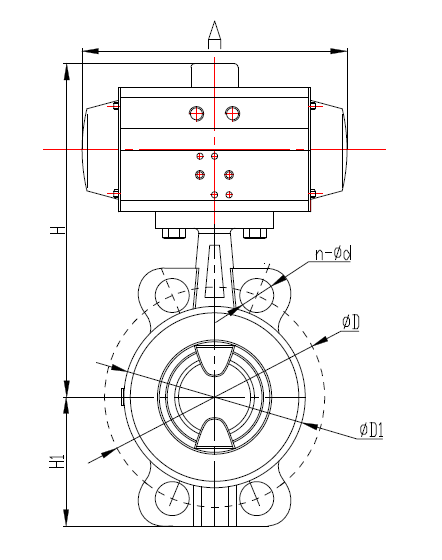

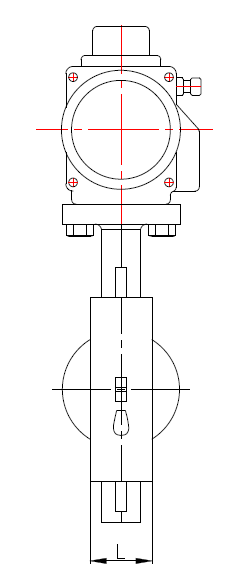

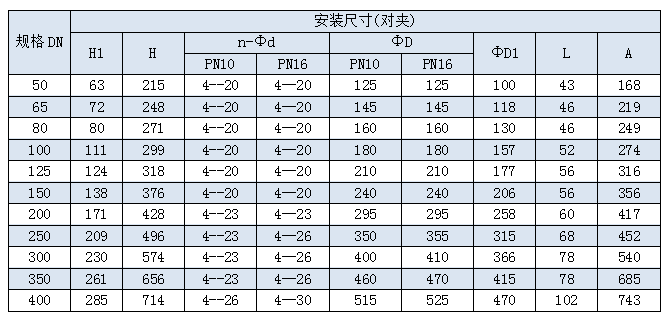

4. product connection size

Product inquiry

Leave your contact information to get a free product quote